Local firms not well prepared for Fourth Industrial Revolution

The core of the Fourth Industrial Revolution is “smart manufacturing plants”. However, Vietnamese enterprises are not fully prepared to access the revolution, Deputy Minister of Industry and Trade (MoIT) Cao Quoc Hung has said.

Digital enterprise – on the way to Industry 4.0 discusses emerging challenges and opportunities generated by the megatrend of digitalisation. (Source:Siemens)

Digital enterprise – on the way to Industry 4.0 discusses emerging challenges and opportunities generated by the megatrend of digitalisation. (Source:Siemens)Hanoi (VNA)

— The core of the Fourth Industrial Revolution is “smart manufacturing

plants”. However, Vietnamese enterprises are not fully prepared to access the

revolution, Deputy Minister of Industry and Trade (MoIT) Cao Quoc

Hung has said.

At the business conference “Digital enterprise – on the way to Industry 4.0,” held in Hanoi on July 20, Hung said together with the foundation of rapid development and high-level integration of science achievements and modern technologies in sectors of digitalisation, bio-technology and physics, the Fourth Industrial Revolution is expected to remarkably change the appearance of manufacturing of the world and Vietnam in the near future.

“Besides this, this model will help enterprises increase their productivity, flexibility and efficiency, as well as shorten production time to make products available in the market, resulting in improvement of an enterprise’s competitiveness. Consumers can also benefit from higher quality, more reasonable prices and favourable products, as expected,” he added.

He said the revolution could create both opportunities and challenges for Vietnam. If Vietnam did not catch up with the world and the region’s development, it would face challenges and effects of backward technologies, decreasing production, abundant skilled labour and copyright violation.

The deputy minister also forecast an inflow of old technologies from developed to developing countries.

Active approaches to state-of-the-art technologies and new development trend of the Fourth Industrial Revolution have been strongly supported by the Vietnamese Government and have been clearly stated in Directive 16/CT-TTg, which was issued by the Prime Minister of Vietnam on May 5, 2017, with regard to the enhancement of the capacity building approach towards the Fourth Industrial Revolution.

Involvement of authorities at all levels, in particular of the business community, is the prerequisite for Vietnam to optimise opportunities generated by this revolution. Supporting companies in accessing information and data, technology transfer and transforming into a digital enterprise will be one of key priorities of the MoIT in the future under Directive 16/CT-TTg.”

Sharing ideas, Tran Viet Hoa, Deputy Director of the ministry’s Department of Science and Technology said local firms would face challenges under the Fourth Industrial Revolution.

Vietnam has 97 percent of small-and-medium sized enterprises with registered capital of 4-7 billion VND (176,000-308,400 USD). The small scale of these enterprises would make them unable to import new technologies into production.

Currently, up to 70 percent of machines and technologies were imported in the 1980s and 1990s. More than 75 percent of the technologies were fully depreciated.

A survey of the department showed that the rate of applying IT in automation and production management has been very low.

Another survey of the Hanoi Small-and-Medium Sized Enterprises Association revealed that businesses were not fully prepared to access the revolution. Up to 55 percent of surveyed firms believed that the revolution would have a significant effect. However, only 12 percent said they have been preparing for the revolution, some 55 percent have been studying about this and 79 percent have been doing nothing, according to the survey.

Christian Berger, German Ambassador to Vietnam, said: “The Fourth Industrial Revolution has enormous potential to deliver. However, close cooperation and dialogue are needed nationally and internationally to ensure that we receive the benefits but avoid the risks from digitalised and automated production. It is essential that in our deliberations, we do not forget that people are the main actors, the main resource and the one goal of any development."

“Siemens terms its path to the Fourth Industrial Revolution as the “Digital Enterprise”. With Digital Enterprise, Siemens offers solutions to address specific requirements of the manufacturing and processing industry. These solutions combine the world of planning and operation to create an integral plant management concept covering the entire lifecycle of an industrial plant. The path to Digital Enterprise is comprised of four core elements that logically build on one another. Each of these core elements is comprised of a unique portfolio that prepares our customers for the revolution. Vietnamese customers are not alone on the way to Industry 4.0. They can count on Siemens,” Siemens Vietnamese president and CEO Pham Thai Lai emphasised.

“To take advantage of the Fourth Industrial Revolution, Vietnam needs to create motivation for enterprises, such as creating favourable conditions or legal framework so that they are confident about joining the revolution. Networking and technology transfer should be the optimal methods for Vietnamese companies on the path to Industry 4.0,” Marko Walde, Chief Representative of AHK Vietnam & Chairman of GBA Vietnam, said.

The event was co-organised by MoIT, the German Embassy in Vietnam, Siemens and German Industry and Commerce Vietnam (GIC/AHK Vietnam). It attracted more than hundred delegates, including senior government policy and decision-makers, business leaders and specialists, who came together to address emerging challenges and opportunities generated by the megatrend of digitalisation with a view to support Vietnamese enterprises on the path to the Fourth Industrial Revolution. VNA

At the business conference “Digital enterprise – on the way to Industry 4.0,” held in Hanoi on July 20, Hung said together with the foundation of rapid development and high-level integration of science achievements and modern technologies in sectors of digitalisation, bio-technology and physics, the Fourth Industrial Revolution is expected to remarkably change the appearance of manufacturing of the world and Vietnam in the near future.

“Besides this, this model will help enterprises increase their productivity, flexibility and efficiency, as well as shorten production time to make products available in the market, resulting in improvement of an enterprise’s competitiveness. Consumers can also benefit from higher quality, more reasonable prices and favourable products, as expected,” he added.

He said the revolution could create both opportunities and challenges for Vietnam. If Vietnam did not catch up with the world and the region’s development, it would face challenges and effects of backward technologies, decreasing production, abundant skilled labour and copyright violation.

The deputy minister also forecast an inflow of old technologies from developed to developing countries.

Active approaches to state-of-the-art technologies and new development trend of the Fourth Industrial Revolution have been strongly supported by the Vietnamese Government and have been clearly stated in Directive 16/CT-TTg, which was issued by the Prime Minister of Vietnam on May 5, 2017, with regard to the enhancement of the capacity building approach towards the Fourth Industrial Revolution.

Involvement of authorities at all levels, in particular of the business community, is the prerequisite for Vietnam to optimise opportunities generated by this revolution. Supporting companies in accessing information and data, technology transfer and transforming into a digital enterprise will be one of key priorities of the MoIT in the future under Directive 16/CT-TTg.”

Sharing ideas, Tran Viet Hoa, Deputy Director of the ministry’s Department of Science and Technology said local firms would face challenges under the Fourth Industrial Revolution.

Vietnam has 97 percent of small-and-medium sized enterprises with registered capital of 4-7 billion VND (176,000-308,400 USD). The small scale of these enterprises would make them unable to import new technologies into production.

Currently, up to 70 percent of machines and technologies were imported in the 1980s and 1990s. More than 75 percent of the technologies were fully depreciated.

A survey of the department showed that the rate of applying IT in automation and production management has been very low.

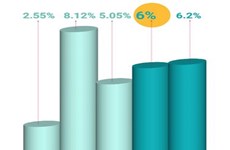

Another survey of the Hanoi Small-and-Medium Sized Enterprises Association revealed that businesses were not fully prepared to access the revolution. Up to 55 percent of surveyed firms believed that the revolution would have a significant effect. However, only 12 percent said they have been preparing for the revolution, some 55 percent have been studying about this and 79 percent have been doing nothing, according to the survey.

Christian Berger, German Ambassador to Vietnam, said: “The Fourth Industrial Revolution has enormous potential to deliver. However, close cooperation and dialogue are needed nationally and internationally to ensure that we receive the benefits but avoid the risks from digitalised and automated production. It is essential that in our deliberations, we do not forget that people are the main actors, the main resource and the one goal of any development."

“Siemens terms its path to the Fourth Industrial Revolution as the “Digital Enterprise”. With Digital Enterprise, Siemens offers solutions to address specific requirements of the manufacturing and processing industry. These solutions combine the world of planning and operation to create an integral plant management concept covering the entire lifecycle of an industrial plant. The path to Digital Enterprise is comprised of four core elements that logically build on one another. Each of these core elements is comprised of a unique portfolio that prepares our customers for the revolution. Vietnamese customers are not alone on the way to Industry 4.0. They can count on Siemens,” Siemens Vietnamese president and CEO Pham Thai Lai emphasised.

“To take advantage of the Fourth Industrial Revolution, Vietnam needs to create motivation for enterprises, such as creating favourable conditions or legal framework so that they are confident about joining the revolution. Networking and technology transfer should be the optimal methods for Vietnamese companies on the path to Industry 4.0,” Marko Walde, Chief Representative of AHK Vietnam & Chairman of GBA Vietnam, said.

The event was co-organised by MoIT, the German Embassy in Vietnam, Siemens and German Industry and Commerce Vietnam (GIC/AHK Vietnam). It attracted more than hundred delegates, including senior government policy and decision-makers, business leaders and specialists, who came together to address emerging challenges and opportunities generated by the megatrend of digitalisation with a view to support Vietnamese enterprises on the path to the Fourth Industrial Revolution. VNA