Hanoi (VNA) - Vietnam’s textile industry could not take full advantage from the new-generation free trade agreements like the Europe-Vietnam free trade agreement (EVFTA) and the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) if it continues dependence on imported raw materials and accessories, according to watchers.

A report from the Ministry of Industry and Trade (MoIT) said Vietnam shipped 22.56 billion USD worth of garment and textile products to foreign countries in the first nine months of this year. Meanwhile, cotton import turnover in the period surged 30.3 percent to 2.41 billion USD, and purchase of fabric increased 13.5 percent year on year to 9.39 billion USD and that of yarn was estimated at 1.78 billion USD, up 34.6 percent.

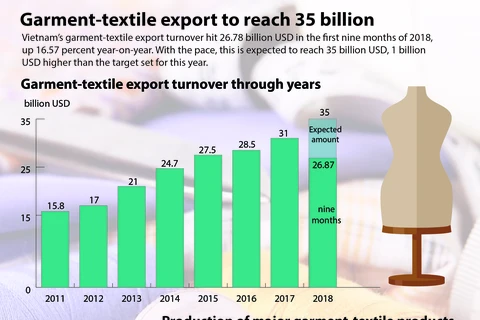

Deputy Minister of Industry and Trade Tran Quoc Khanh has said the garment and textile sector is expected to earn high revenue of 35 billion USD this year. “We have enjoyed high export earnings but we do not have materials,” he pointed out.

Particularly, when the EVFTA and the CPTPP take effect in the end of this year, with tax lines cut to zero, Vietnamese garment and textile products will have opportunities to expand its market share in Canada, New Zealand and Australia. However, the two deals set high requirements in terms of thread and fabric origin, which poses barriers to the industry when it is tangled in the middle, productive in terms of final products but grinding to a halt in the production of materials.

Pham Tat Thang, a senior researcher at the MoIT, said domestic textile firms are able to produce 0.8 billion metres of fabric each year, meeting only around 13 percent of the total demand. This means the country still has to import 5.2 billion metres of fabric annually.

Thang said that even the home-made amount is not qualified to make high-quality products. In fact, many businesses have to import more than 90 percent of its material to satisfy production.

Chairman of the Vietanm Textile & Apparel Association (VITAS) Vu Duc Giang said that the association has called for foreign investments to ensure sufficient supply for the sector. During January-August, the country secured over 2 billion USD in foreign direct investments (FDI) in the garment and textile industry. Those include a 50 million USD sheep wool yarn spinning plant in Da Lat city, invested in by German Sudwolle, and a 13.8 million USD sewing threads factory in Quang Nam province by German Amnn Group.

Domestic firms have also invested heavily in weaving and dying. Advanced technology has been applied in Phong Phu International JSC in softerner wash process for its jeans and khaki products. Meanwhile, Bao Minh company recently opened its weaving factory in Nam Dinh province, with a designed capacity of over 35 million metres of fabric each year – 70 percent of which will be yarn-dyed.

Giang expressed his belief that with the presence of new weaving companies, the sector will have sufficient material to ensure its sustainable development.-VNA

VNA