Hanoi (VNA) - Vietnam has a significant opportunity to become part of the semiconductor industry's global revolution. However, the biggest challenge it faces is the lack of a skilled workforce in the field.

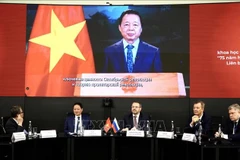

Experts at a seminar held on April 19 emphasised that collaboration with international partners, particularly countries and regions that are leading in semiconductor technology, is a highly effective solution to address this issue and enhance the quality of training.

Vast opportunity

In his address at the seminar, Vu Anh Tu, Chief Technology Officer of FPT Group, highlighted that the global semiconductor industry reached 620 billion USD in revenue in 2023, with projections to surpass 1 trillion USD by 2030. Vietnam is poised to play a key role in this revolution as it has been identified as a potential participant in the semiconductor value chain.

Large companies are already investing in semiconductor research and development centres in Vietnam, while domestic businesses are showing increasing interest in the sector.

FPT has already launched an R&D centre in Da Nang, aiming to establish the city as the "Silicon Valley” of the region. By 2030, FPT plans to recruit around 7,000 semiconductor engineers. The company is ramping up its training efforts through collaboration with over 20 global universities. Tu also stressed that the semiconductor sector offers high salaries, presenting significant opportunities for students pursuing careers in this field.

Do Tien Thinh, Deputy Director of the National Innovation Centre, noted that semiconductor is a critical core technology within the IT industry. He emphasised that for any nation to achieve technological independence, it must master core technologies like semiconductor.

Semiconductors are crucial not only for the economy but also for national security. In the US, the semiconductor industry is seen as a strategic sector with implications for national security, Thinh explained.

Thinh also pointed out that Vietnam’s role in the global semiconductor supply chain is growing. The government has issued two strategic decisions to facilitate the development of the sector and to cultivate a highly skilled workforce.

The semiconductor technology involves three main processes: design, packaging, and testing. Vietnam has the potential to engage in packaging and testing, but the national strategy focuses on developing expertise in design, Thinh said.

International cooperation to enhance training quality

Despite the immense opportunity, experts agree that Vietnam’s greatest challenge lies in the lack of a trained workforce. Vietnam will need to train 50,000 to 100,000 semiconductor engineers by 2030, yet current statistics show that the country only has around 5,000 engineers in the field.

Furthermore, most universities are only beginning to offer semiconductor training programmes, and they lack the necessary personnel and facilities to deliver these programmes effectively. Training in this sector is costly due to the need for expensive equipment and resources.

However, Thinh remains optimistic, highlighting that Vietnamese people are good at mathematics and natural sciences, which is a solid base for semiconductor training. The Government’s strategy is to focus on developing talent in chip design, the most critical aspect of semiconductor production.

He explained that although Vietnam currently lacks semiconductor manufacturing plants, the Government is supportive of efforts to improve the quality of training in the semiconductor sector. Various initiatives have been introduced such as investment in 18 key laboratories, forging connections with major semiconductor-producing economies, and providing financial support for universities to acquire expensive equipment and technology.

Hoang Viet Ha, Director of the International Training Institute at FPT University, shared that the institute has recently signed a cooperation agreement with Asia University in Taiwan (China) to train semiconductor professionals. Under this agreement, students will spend the first two years at FPT University, focusing on IT and artificial intelligence programmes, and then move to Taiwan for two additional years to study semiconductor technology in depth.

The programme, which will be conducted entirely in English, also includes Chinese language training to ensure students are well-prepared to learn in Taiwan, a global hub for the semiconductor industry. In Taiwan, students will have the opportunity to gain hands-on experience at companies, which is a major advantage given the proximity between universities and businesses there.

Thinh said he believes this international collaboration model matches Vietnam’s workforce development strategy. Of the 50,000 to 100,000 engineers needed by 2030, he suggests that most of them should be trained to meet international market demand, with the understanding that many will eventually return to Vietnam after gaining experience abroad.

The National Innovation Centre has also joined hands with two major universities in sending 60 individuals abroad for master’s courses in semiconductor technology. These individuals will receive scholarships from major companies and return to Vietnam after gaining experience while working in developed countries, Thinh said.

From the perspective of recruitment, Nguyen Vinh Quang, CEO of FPT Semiconductor, shared that many Vietnamese graduates still require further training after graduation due to a lack of deep semiconductor knowledge. Quang emphasised that international training partnerships are a strategic move that will help Vietnam access advanced technologies and teaching methods, enabling the country to quickly improve its competitiveness in the global semiconductor industry./.