Hanoi (VNA) – A growing number of foreign clients have expressed interest in negotiating new shipbuilding contracts, however, many domestic shipyards are already operating at full capacity and are unable to take on additional orders.

Currently, many members of the Sai Gon Shipbuilding and Marine Industry Co., Ltd (SBIC) have secured orders through 2026–2027. However, due to lingering debt burdens from the past and the inability to access bank loans for reinvestment and production expansion, several shipyards have been forced to reluctantly turn down new contracts.

Forced to say no to new contracts

A wide range of vessel series are currently under construction at SBIC’s shipyards. Orders from shipowners continue to pour in, yet with limited capacity, many firms have had no choice but to reluctantly deny additional contracts.

Despite high demand, constrained resources have left shipbuilders “shaking their heads” at opportunities they cannot fulfill.

At subsidiaries of SBIC such as Bach Dang, Nam Trieu, Pha Rung, and Song Cam, their workshops are alive with the sounds of hammers, cutting machines, and grinders, factories lit up by the bright flashes of welding torches. Each section of the vessels is meticulously crafted by workers, with every cut and weld carried out in careful detail.

Tran Van Rung, Deputy General Director of the Pha Rung Shipbuilding Company, said the company has secured enough work to last through 2027. With favourable freight rates and positive signals in both domestic and global shipbuilding markets, demand for new vessels has surged. As a result, major shipbuilding nations like China, the Republic of Korea, and Japan are overwhelmed with orders, prompting many foreign shipowners to turn to Vietnam to place contracts.

Many domestic shipowners are requesting contracts for bulk carriers ranging from 6,000 to 30,000 tonnes, Rung said. Foreign clients have also expressed interest in negotiating contracts, but the company lacks the capacity to take on additional orders.

The series of 14 offshore wind power service vessels is a collaborative project between the Ha Long Shipbuilding Co., Ltd and Damen Group of the Netherlands. These vessels are among the most modern and technically complex ships ever built in Vietnam and three of those have already been launched.

Nguyen Tuan Anh, General Director of the Ha Long Shipbuilding Co., Ltd, shared that the firm is currently building a range of vessels for both domestic and international partners, including a 120-metre overnight cruise ship, a cable-laying vessel, a five-star passenger ship, and a 45,000-DWT bulk carriers.

With the existing contracts, the company has secured enough work to keep its workforce employed through the end of 2027. In fact, the company has had to turn down several new orders despite strong interest from shipowners.

Nguyen Ba Son, Deputy General Director of the Bach Dang Shipbuilding Co., Ltd, said his company is currently building different types of vessels including chemical tankers, liquefied gas carriers for export to Italy, and general cargo ships.

By the end of this month, the company is expected to deliver a liquefied gas tank carrier. It is also building a 9,300 sq.m oil and chemical tanker, scheduled for launch in early June and delivery in October. Additionally, two 6,600 DWT cargo ships are set for handover by the end of this year.

Made-in-Vietnam ships meet European standards

At the 10th International Exhibition on Shipbuilding and Offshore Technology (Vietship 2025) held in Hanoi in early March, many contracts and agreements for new builds and shipbuilding services were signed between domestic and international partners, with a total estimated value of around 60 million USD. This reflects the growing capability and position of Vietnam’s shipbuilding industry in the international market.

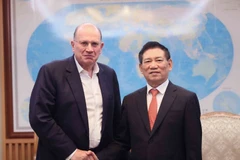

After personally inspecting all three offshore wind power service vessels made by the Ha Long Shipbuilding Co., Ltd, Willem van der Wel, CEO of Windcat – a subsidiary of shipowner CMB.Tech, remarked that the quality of the ships was on par with similar vessels built at European shipyards.

Recently, the Bach Dang Shipbuilding Co., Ltd became one of the first in Vietnam to successfully build an independent liquefied natural gas (LNG) storage tank for a 4,500 sq.m LNG carrier exported to Italy.

Notably, Vietnam was also responsible for designing the tank, said Son of the Bach Dang shipyard. He added that this LNG carrier exported to Italy is two to three times more technically challenging than standard vessels, and this is the first time Vietnam has built this type of ship./.